First, product introduction

Fresh air ventilator is based on the other side of the air supply in the closed indoor side of the wind, the indoor will form a "fresh air flow field" principle of design and development. It relies on mechanical air supply, induced draft, forcing the formation of fresh air flow field within the system. It is a new type of environmental protection appliance keeping the indoor air clean and fresh at all times. This kind of independent indoor air replacement and purifying circulatory system can input natural fresh air while eliminating the polluted indoor air, and then treat the fresh air input into the room first through filtration, sterilization, heating, oxygenation and the like.

Shandong Century Changlong New Energy Co., Ltd. production of fresh air ventilator by the National Air Conditioning Equipment Quality Supervision and Inspection Center for testing, the indicators have reached the relevant standards.

1, plate-fin heat exchanger

2, plate fin heat recovery Overview:

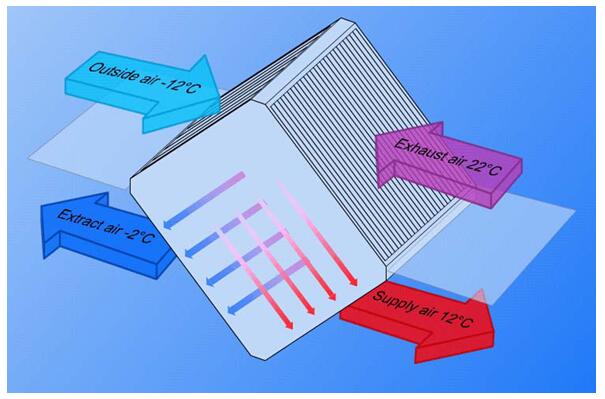

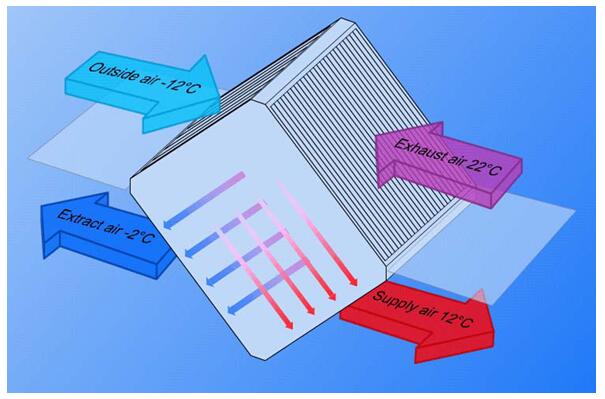

Plate-fin heat exchangers belong to a direct exchange of air and air stationary heat exchanger, it does not require heat transfer through the intermediate medium, there is no rotating system, therefore, stationary plate-fin heat exchanger (also known as fixed Type heat exchanger) is an ideal energy recovery equipment. Stationary plate-fin heat exchangers are sensible or total heat recovery in the presence of two air currents on both sides of the bulkhead with differential temperature and partial pressure of water vapor.

In plate-fin heat exchangers, the two streams cross the flow through the heat exchanger. Sensible heat exchanger separator is impermeable, with good thermal conductivity of the material, generally mostly aluminum materials. The total heat exchanger is a transmissive air-to-air heat exchanger whose partitions are made from a treated material that has good heat and moisture transmission characteristics. Temperature (sensible heat) mechanism of exchange is the flow of air at different temperatures on both sides of the medium, the heat through the conduction of the exchange. The exchange of humidity (latent heat) in the total heat exchanger is carried out by two mechanisms:

① through the media on both sides of the water vapor partial pressure humidity exchange.

② high humidity side of the water vapor absorbent is absorbed by the capillary action of paper fibers to the low-wet side release.

3, plate fin heat recovery:

A, static heat exchanger, in order to facilitate the layout of the air flow channel within the machine and reduce the size of the machine, small and medium sized fresh air ventilator with flat cross static heat exchanger, its working principle is: cold, hot air movement The directions are perpendicular to each other, and the air flow in the heat exchanger belongs to the convective heat transfer property in the turbulent boundary layer, which has high heat exchange efficiency.

B, sensible heat exchanger and total heat exchanger, sensible heat exchanger made of aluminum foil material, high temperature conductivity, long life, suitable for indoor and outdoor temperature difference between the small difference in humidity. The whole heat exchanger is made of special fiber made of paper with special technology. This material has the characteristics of high moisture permeability, good air tightness, tear resistance and aging resistance. The whole heat exchanger is suitable for indoor and outdoor temperature difference small humidity difference in the area.

Second, fresh air ventilation unit features:

1, two-way ventilation indoor and outdoor two-way ventilation, equal replacement of fresh air.

2, filtration treatment Fresh air filtration treatment in line with the construction regulations. Filters prevent dust and other contaminants from entering the room.

3, Energy-efficient built-in static heat exchanger, the heat exchange efficiency is greater than 70%, hot and cold load (room temperature) is not affected by fresh air, greatly reducing the energy required for fresh air treatment, energy efficient.

4, easy to use variety of models, suitable for building units from 15m2 to 1100m2, integrated structure, built-in heat exchanger, dual fans, filters, just connect the power supply and air duct can be used, not only simplify the design, Various renovation projects.

5, safe and reliable Low noise fan and the internal noise reduction to prevent the impact on the outside world, the whole machine without moving parts outside the fan, almost no maintenance, to ensure long-term stable and reliable work.

6, low cost and high efficiency alternative fresh air treatment equipment, do not have a separate operating room, equipment investment and construction area can be reduced, the use of heat recovery technology energy saving, significantly reduce operating costs, saving fresh air processing energy consumption of more than 30%, no cold Heat supply, integrated structure to reduce maintenance workload.

7, the production of refined equipment components are made of high quality steel, environmentally friendly materials, aluminum frame, high quality, exquisite appearance.

Third, fresh air ventilation unit configuration:

1. Filter configuration:

The finned fin heat recovery air channel is relatively wide, so the air quality is not too high, but dirty, high dust content of air will reduce its efficiency, so the fresh air exhaust into the side should be Respectively plus initial filtration, initial filtration level should be G4.

2. Condensate configuration:

Plate fin heat recovery is divided into sensible heat recovery and total heat recovery, when the use of sensible heat recovery, send the exhaust temperature difference in the larger case, especially in the northern winter, the fresh air temperature is much lower than the dew point of the exhaust temperature There will be condensate discharge at this time. Therefore, there should be a water receiving tray under the inclined plate for organized drainage. When using full heat recovery, you can not set the water tray.

3 fan configuration:

Selection of small and medium-sized fresh air ventilator outer rotor type high efficiency and low noise centrifugal fan. All fan impellers through the dynamic balance test, the use of self-aligning impeller bearings maintenance-free bearings have been filled with good high temperature grease, long service life. The external rotor fan used by the unit has low noise and good aerodynamic performance. The connection structure between the impeller and the volute makes the replacement of the impeller bearings and the motor very convenient during maintenance.

Fourth, fresh air ventilation unit structure:

The structure of the unit adopts the frame plate type (frame beam and guard plate). Modular product design, making the parts to achieve a standardized and universal, greatly improving the production efficiency and shorten the processing cycle.

The frame of the unit is a closed aluminum alloy profile rolled by a special rolling equipment, the cross-sectional shape is □, the material of the tank plate is a color steel plate, the color steel plate base material is a hot-dip galvanized steel plate, two color resin paint layers are coated on the front face , The back coated with a layer, so its folding resistance, weather resistance, corrosion resistance, acid, alkali, salt, fade in 15 years; inside and outside the fender pressure injection δ = 30mm thick polystyrene or polyurethane insulation materials, Greatly improving the rigidity and corrosion resistance of the unit shell; at the same time, due to the non-water absorption of the insulation material, the unit will not reduce the insulation performance due to dampness, so the thermal insulation performance and the airtightness performance of the unit are excellent and durable. The color of the color plate is pearl white.

The internal sheet metal parts of the unit are made of galvanized steel. The unit is sealed with sealant between the box plate and the frame and between segments. The unit has high temperature resistant (+90 ℃), low temperature resistant (-60 ℃), sealed Good sex, long life and other characteristics;